Ultra-precision filtration coolant system|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

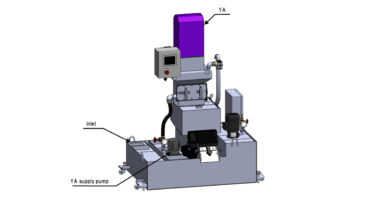

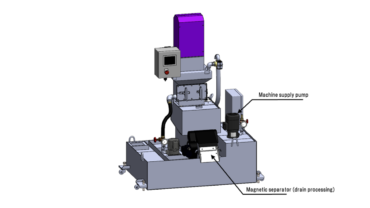

Ultra-precision filtration coolant system SB Filter YA

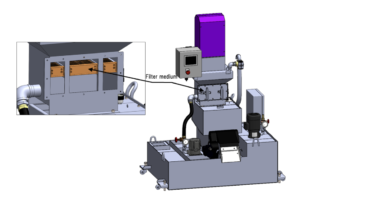

Ultra-precision filtration system that uses steel balls as the filter medium.

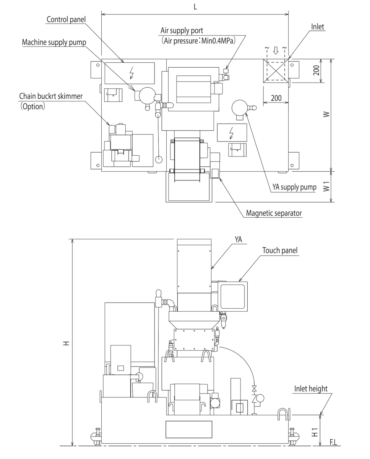

The filter media is automatically cleaned by performing operations on the touch panel.

Optimum for grinding sludge processing on honing machines and super-finishing machines.

<PATENTED>

Features

- The filtration and cleaning cycle is controlled by the timer.

- The operation can be performed on the touch panel.

The operation mode can be switched between automatic and manual modes.Even if an abnormality occurs, it is displayed on the touch panel screen. - The filter medium (steel ball) can be removed from the main body for cleaning and maintenance.

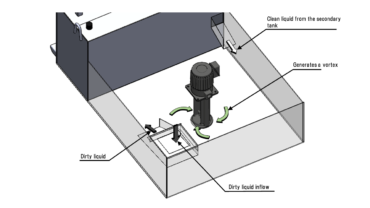

- A vortex is generated in the primary tank using the inflow of the primarily filtered clean liquid and the overflow of the secondary tank.With its centripetal force*, sludge and abrasive grains are collected in the center of the tank.

- By improving the primary tank structure, the rotating velocity of the vortex flow has tripled compared to before the improvement.Improved centripetal force reduces sludge and abrasive deposits in the tank.

- This product is not a bag type or cartridge type, so there is no need to replace the element.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.* Refers to the force that acts toward the center of the circle.Vortex.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material |

| Processing details | Grinding |

| Work material | FC/FCD Steel |

| Chip shape | |

| Grinding chip size | Ultrafine particles (5 μm to 10 μm) Fine particles (10 μm to 100 μm) |

| Machine tool | Honing machine Super finishing machine (Super finisher) |

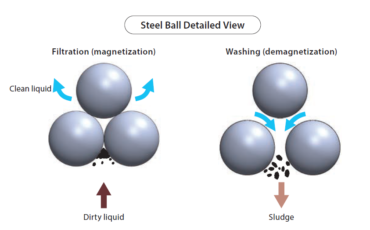

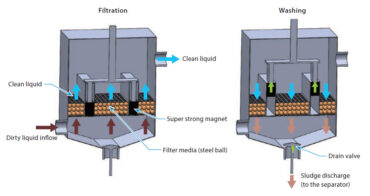

Mechanism

- A vortex is generated when the dirty liquid flows into the primary tank.With its centripetal force*, sludge accumulates in the center of the tank.

* Refers to the force that acts toward the center of the circle.Vortex. - The YA supply pump in the center of the tank pumps the accumulated sludge.

- The dirty liquid flows into the filtration tank with the magnetized filter medium (steel ball).

Sludge is adsorbed and filtered as it passes through the filter medium (steel balls). - The clean liquid is sent to the secondary tank.

- The filter medium (steel ball) is demagnetized to remove the sludge adsorbed on the filter medium (steel ball).

Clean the filter medium (steel ball) using the clean liquid remaining in the filtration tank. - After the filter medium is cleaned, the liquid mixed with sludge is supplied to the magnet separator to act as a drain.

- The drain is filtered by the magnetic separator.

The sludge is discharged to the outside of the main body, and the clean liquid is sent to the primary tank. - The clean liquid from YA is stored in the secondary tank and supplied to the machine.

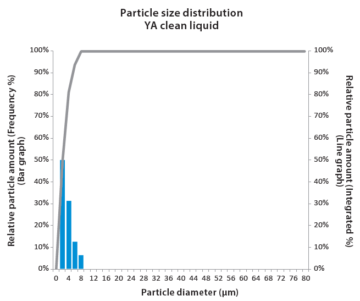

Before-and-after coolant status by filtration

Left: Before - Dirty liquid

Right: After - Clean liquid

* This is the result of our experiments, and it does not imply that this level of cleaning ability has been verified.

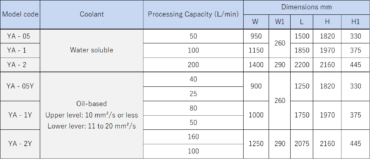

Specifications

Filtration accuracy

5 μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Grinding machine

Coolant: Water soluble

Processing flow rate: 50 L/min

Chip material: FC

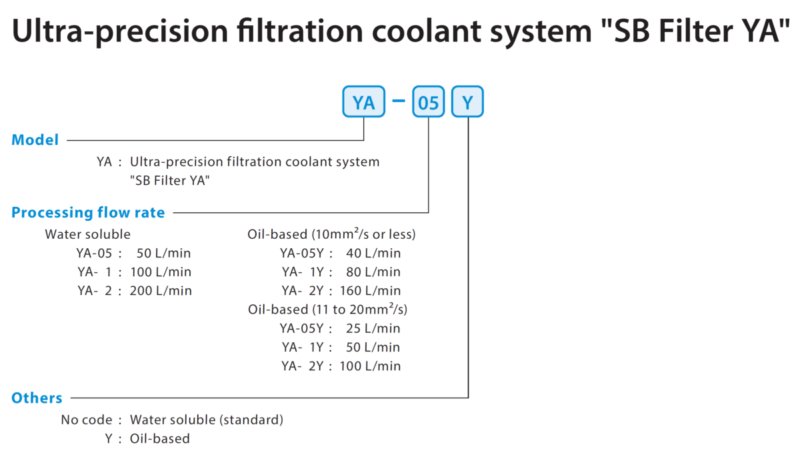

Processing flow rate

Water soluble

- YA-05 50L/min

- YA-1 100L/min

- YA-2 200L/min

Oil-based (10 mm2/s or less)

- YA-05Y 40L/min

- YA-1Y 80L/min

- YA-2Y 160L/min

Oil-based (11 to 20 mm2/s)

- YA-05Y 25L/min

- YA-1Y 50L/min

- YA-2Y 100L/min

* When the oil viscosity exceeds 20 mm 2/s, please consult us.

* The oil viscosity is the value at 40℃.

Product weight

Water soluble

- YA-05 365kg

- YA-1 415kg

- YA-2 620kg

Oil-based

- YA-05 365kg

- YA-1 415kg

- YA-2 620kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

Model code

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* When the oil viscosity exceeds 20 mm 2/s, please consult us.

* The oil viscosity is the value at 40℃.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.