Drastic cleaning reduction for cutting coolant system|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

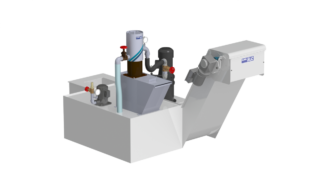

Drastic cleaning reduction for cutting coolant system SLC

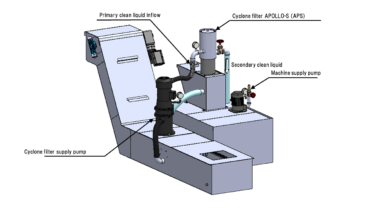

Cutting chip processing system that combines the punching filter and a new cyclone filter in a unique configuration.

The cyclone filter filters cutting chips, so clean liquid can always be supplied to the machine.

<PATENTED>

Features

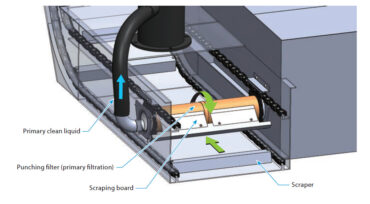

- The primary filtration is performed by the punching filter conveyor, and the secondary filtration is performed by the cyclone filter.

- The punching filter is always in contact with the scraping board and rotates to prevent clogging.

- No backwashing is required, so no mist is generated, which helps improve the environment in the factory.

- The chip discharge port of the conveyor has a structure that drains liquid, which ensures that chips are drained before being discharged.

This processing reduces the load to carry out coolant (means that coolant is discharged together with chips). - The primary clean liquid is supplied directly from the conveyor (punching filter) to the cyclone filter, so no primary tank is required.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

| Coolant | Water soluble |

|---|---|

| Category | Non-magnetic material |

| Processing details | Cutting |

| Work material | Aluminum Stainless Titanium Mixed chips (aluminum + FC or sintered metal) |

| Chip shape | Granular Small curl-shaped (50 mm or less) Small curl-shaped (51 mm to 100 mm) |

| Grinding chip size | |

| Machine tool | Machining center Gun drill machine Cutting specialized machine |

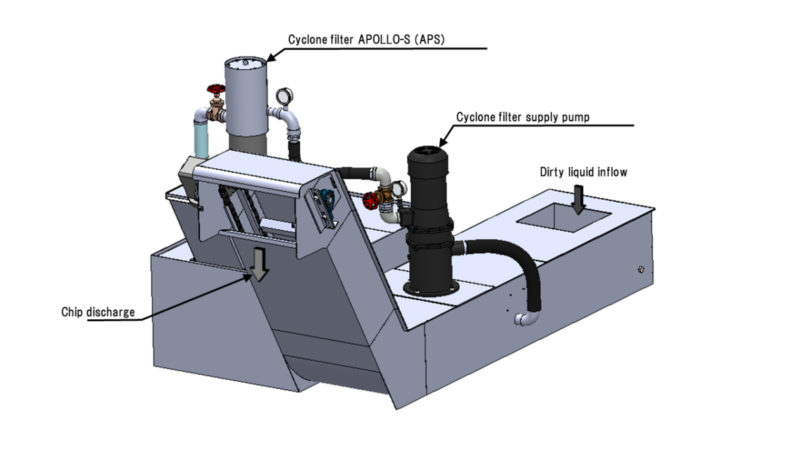

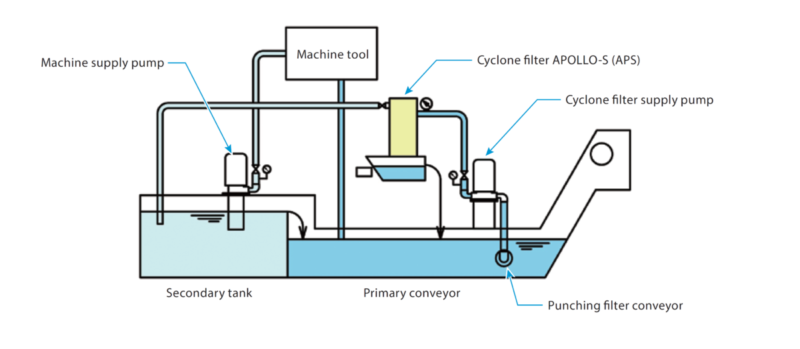

Mechanism

- The dirty liquid flows onto the conveyor.

- The dirty liquid is supplied to the cyclone filter (AP) via the punching filter that is rotated by the coolant pump.

- The primary clean liquid that was primarily filtered when passing through the punching filter is secondarily filtered by the cyclone filter (AP).

- The secondary clean liquid flows into the tank and is supplied to the machine by the pump.

- Chips captured in the punching filter are scraped off by the scraping board and settle on the bottom of the conveyor.

- Chips that have settled on the bottom of the conveyor are conveyed by the scraper.

- Chips are temporarily stored in the conveyor outlet, drained, and then discharged.

Specifications

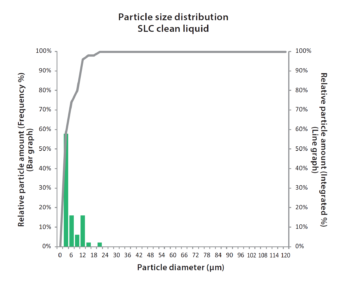

Filtration accuracy

10μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Grinding machine

Coolant: Water soluble

Processing flow rate: 100 L/min

Chip material: Steel

* This is the numeric value based on the Cyclone filter APOLLO-S (APS).

Processing flow rate

Water soluble

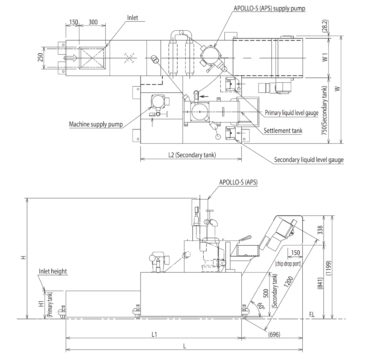

- SLC-1(ALL45HLA-335(11-1)+APS-1) 100L/min

- SLC-2(ALL65HLA-397(12-2)+APS-2) 200L/min

Product weight

- SLC-1(ALL45HLA-335(11-1)+APS-1) 585kg

- SLC-2(ALL65HLA-397(12-2)+APS-2) 690kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

Geared motor

- SLC-1(ALL45HLA-335(11-1)+APS-1) 100W

- SLC-2(ALL65HLA-397(12-2)+APS-2) 100W

Flow sheet

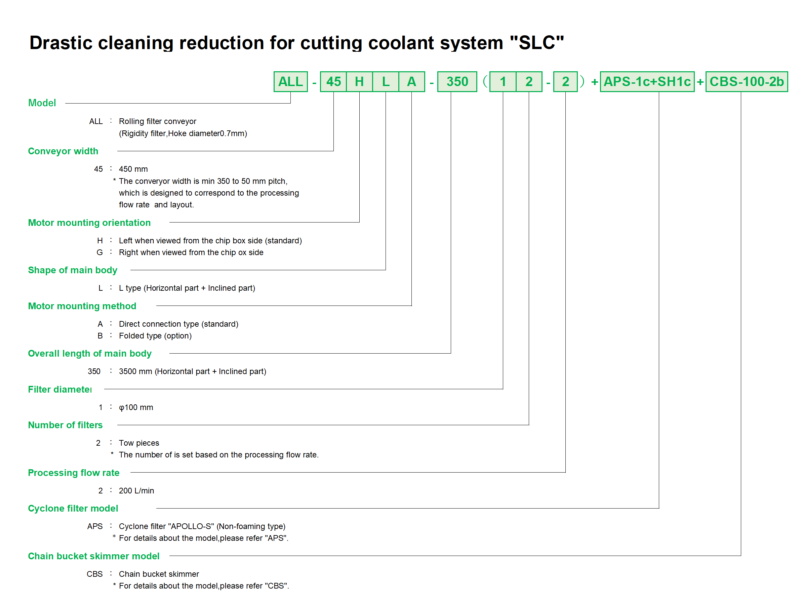

Model code

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.