Drastic cleaning reduction for grinding coolant system|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Drastic cleaning reduction for grinding coolant system RTG

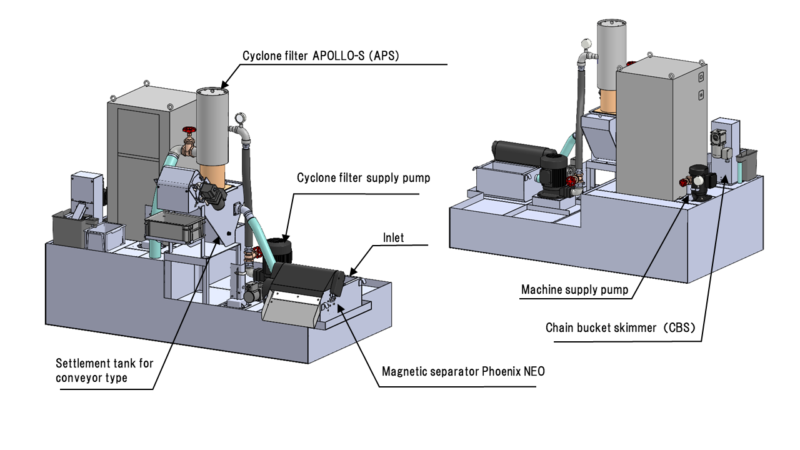

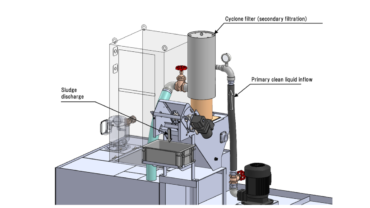

Grinding system equipped with a new magnetic separator and a new cyclone filter in a uniquely designed tank structure.

Optimum for grinding sludge processing of magnetic materials.

<PATENTED>

Features

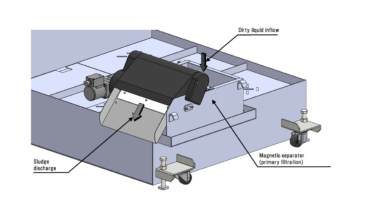

- Suitable for sandy and cottony magnetic sludge.

- The primary filtration is performed by the magnetic separator, and the secondary filtration is performed by the cyclone filter.

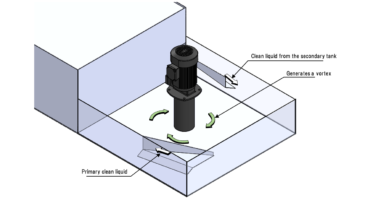

- A vortex is generated in the primary tank using the inflow of the primarily filtered clean liquid and the overflow of the secondary tank.With its centripetal force*, sludge and abrasive grains are collected in the center of the tank.

- By improving the primary tank structure, the rotating flow speed of the tank has increased about three times compared to before the improvement. Improved centripetal force* reduces sludge and abrasive deposits in the tank.As no shower pump is required, power consumption is reduced.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.* Refers to the force that acts toward the center of the circle.Vortex.

| Coolant | Water soluble |

|---|---|

| Category | Magnetic material |

| Processing details | Grinding |

| Work material | FC/FCD Steel |

| Chip shape | Sandy Cottony |

| Grinding chip size | Ultrafine particles (5 μm to 10 μm) Fine particles (10 μm to 100 μm) Coarse particles (0.1 mm to 0.5 mm) |

| Machine tool | Grinding machine Tool grinding machine |

Product introduction video

Mechanism

- The dirty liquid is primarily filtered by first passing through the magnetic separator.

- The primarily filtered clean liquid flows into the primary tank to generate a vortex.

With its centripetal force, sludge and abrasive grains accumulate in the center of the tank. - The supply pump in the center of the tank pumps the accumulated sludge and abrasive grains.

- The primarily filtered clean liquid is secondarily filtered by the cyclone filter.

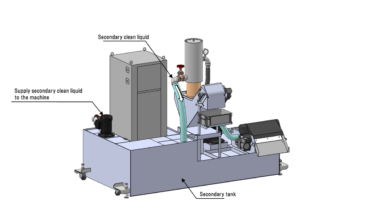

- The secondarily filtered clean liquid flows into the secondary tank, and it is supplied to the machine by the pump.

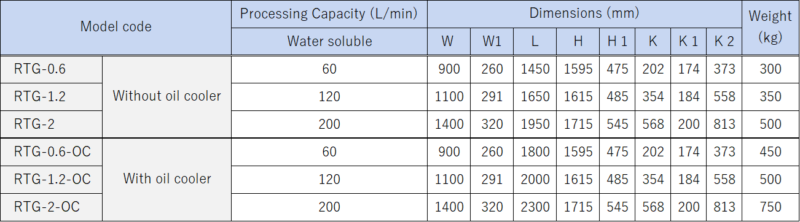

Specifications

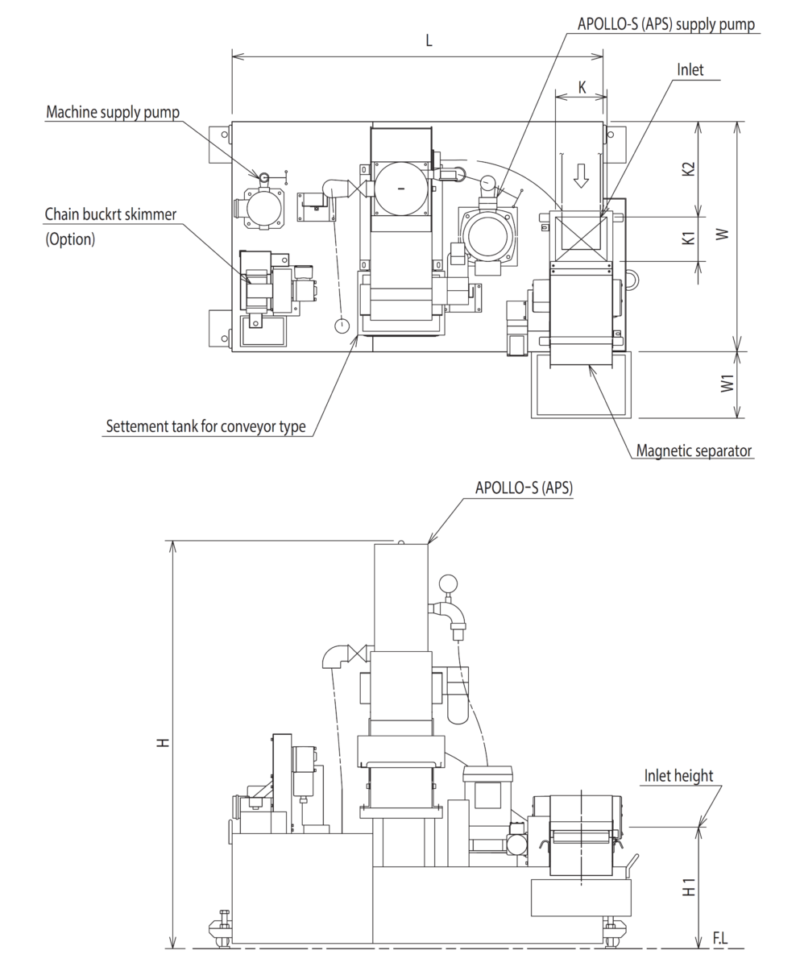

Dimensional drawing

Dimension table

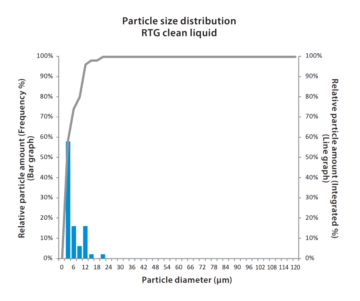

Filtration accuracy

10 μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Grinding machine

Coolant: Water soluble

Processing flow rate: 100 L/min

Chip material: Steel

Processing flow rate

Water soluble

- 60 L/min 120 L/min 200 L/min

Product weight

Without oil cooler

- 60 L/min 350 kg

- 120 L/min 400 kg

- 200 L/min 550 kg

With oil cooler

- 60 L/min 450 kg

- 120 L/min 500 kg

- 200 L/min 650 kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

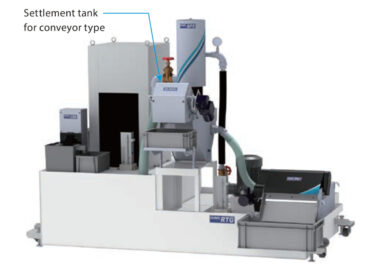

Option

- Settlement tank for conveyor type (Drive motor: 25W)

- Chain bucket skimmer CBS

- Relay terminal box

- Control panel, Operation box

* Please contact us for details.

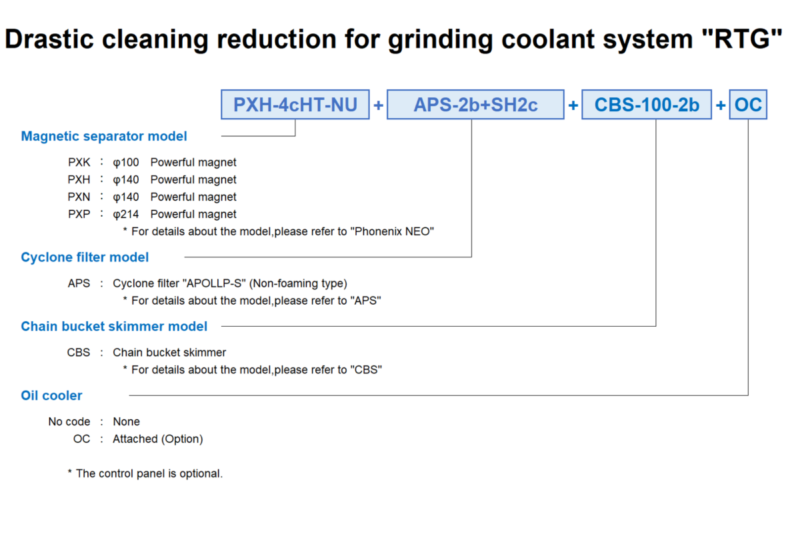

Model code

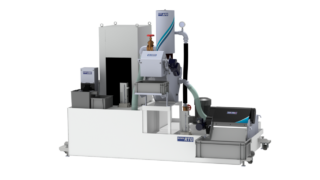

Product Photo (Example)

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.