Rolling filter conveyor|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Rolling filter conveyor MAL

Conveyor that supports both magnetic and non-magnetic materials with a combination of magnet and punching filter.

Optimum for those who process both magnetic and non-magnetic materials using a single machine tool.

Features

- A single machine is suitable for chips of both magnetic materials and non-magnetic materials.

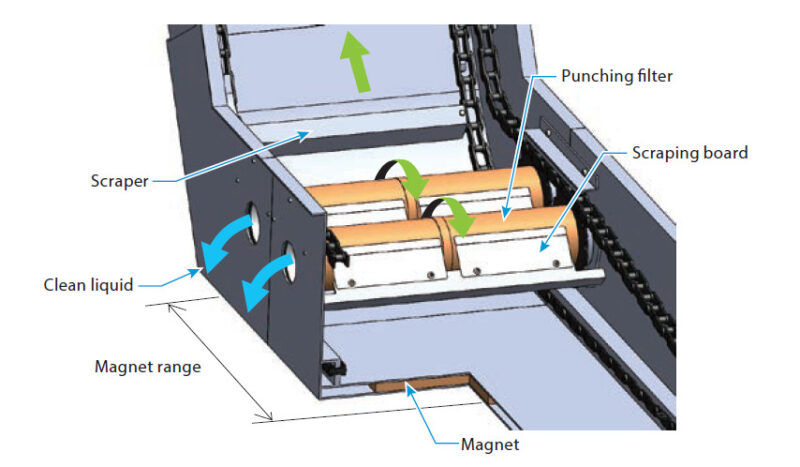

- The magnet installed on the bottom of the conveyor captures magnetic chips.

- The punching filter captures non-magnetic chips.

- The punching filter is automatically cleaned by constantly rotating in contact with the scraping board, preventing it from becoming clogged.

- No backwashing is required, so no mist is generated, which helps improve the environment in the factory.

- The chip discharge port of the conveyor has a structure that drains liquid, which ensures that chips are drained before being discharged.

This processing reduces the load to carry out coolant (means that coolant is discharged together with chips). - This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material Non-magnetic material |

| Processing details | Cutting |

| Work material | Mixed chips (aluminum + FC or sintered metal) |

| Chip shape | Granular Small curl-shaped (50 mm or less) Small curl-shaped (51 mm to 100 mm) |

| Grinding chip size | |

| Machine tool | Machining center Broaching machine NC lathes Automation machine Gear cutting machine Gun drill machine Cutting specialized machine |

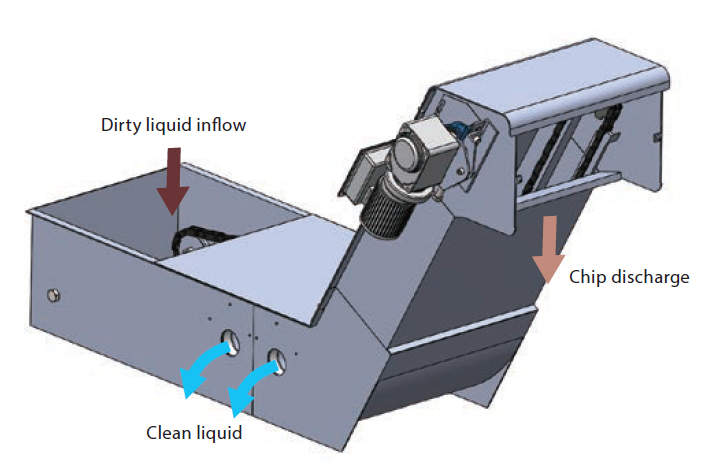

Mechanism

- The dirty liquid flows onto the conveyor.

- Magnetic chips are captured by the magnet installed on the bottom of the conveyor.

- The dirty liquid is filtered when it passes through the rotating punching filter.The resultant clean liquid flows from the inside of the punching filter to the tank.

- Chips captured in the punching filter are scraped off by the scraping board and settle on the bottom of the conveyor.

- Magnetic chips captured by the magnet on the bottom of the conveyor and chips that have settled on the bottom of the conveyor are conveyed by the scraper.

- Chips are temporarily stored in the conveyor outlet, drained, and then discharged.

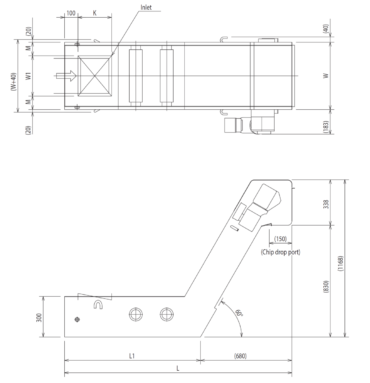

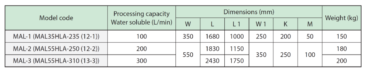

Specifications

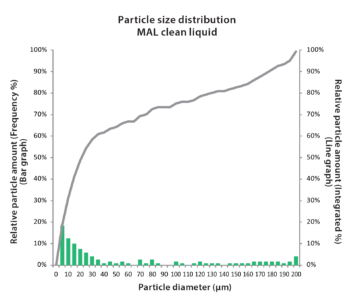

Filtration accuracy

200μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Machining center

Coolant: Water soluble

Processing flow rate: 700 L/min

Chip material: Aluminum

Processing flow rate

Water soluble

- MAL-1(MAL35HLA-235(12-1)) 100L/min

- MAL-2(MAL55HLA-250(12-2)) 200L/min

- MAL-3(MAL55HLA-310(13-3)) 300L/min

Product weight

- MAL-1(MAL35HLA-235(12-1)) 150kg

- MAL-2(MAL55HLA-250(12-2)) 180kg

- MAL-3(MAL55HLA-310(13-3)) 200kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

Geared motor

100W

Option

- Cyclone filter APOLLO

- Chain bucket skimmer CBS

- Relay terminal box

- Control panel, Operation box

* Please contact us for details.

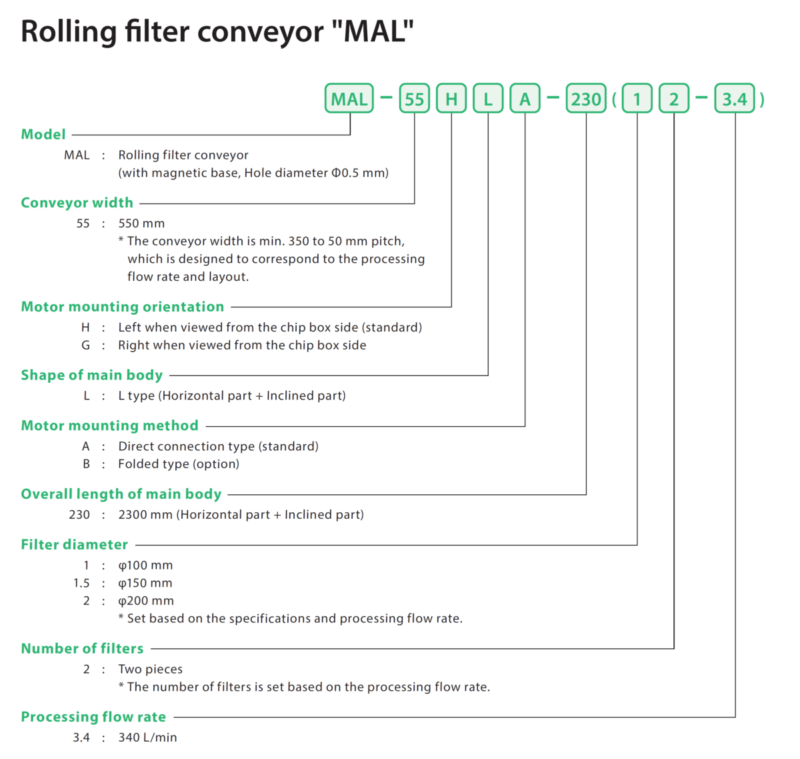

Model code

Product Photo (Example)

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.