Cyclone filter APOLLO-S|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Cyclone filter APOLLO-S APS

Cyclone-type secondary processing unit that you can use extensively regardless of magnetic or non-magnetic materials.

Compatible with fine cutting chips and grinding sludge.

The defoaming mechanism supplies the non-foaming clean liquid.

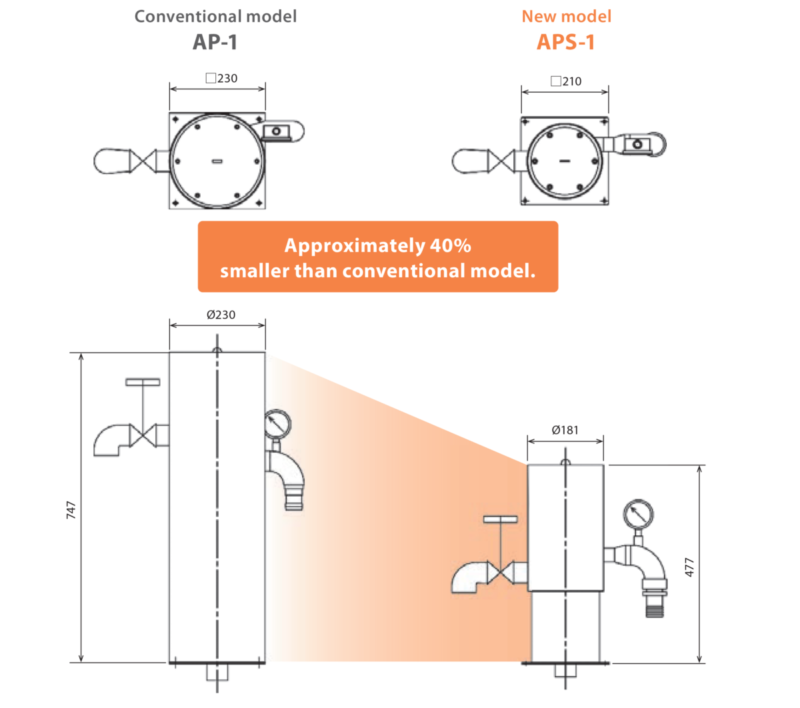

The main body has been downsized while maintaining the filtration accuracy and defoaming mechanism of the old type.

<PATENTED>

Features

- Cyclone-type secondary filtration equipment that deals with coolant containing fine chips and sludge.

- It has a built-in defoaming mechanism that suppresses the foaming of clean liquid.

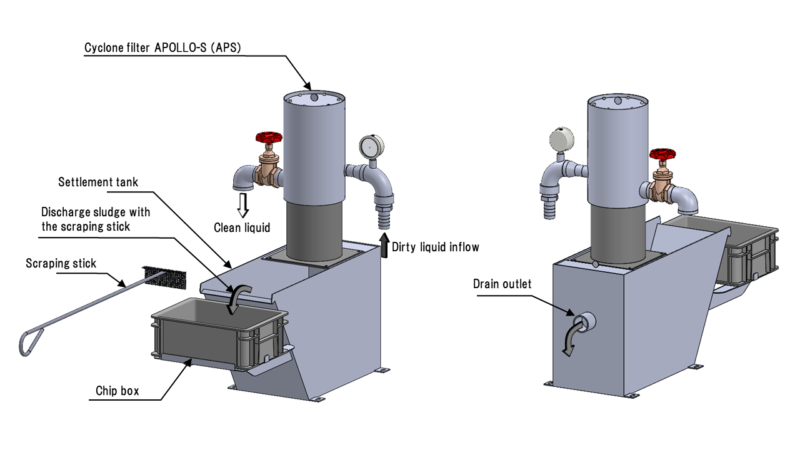

- By combining this equipment with the settlement tank or the settlement tank for conveyor type, drained chips and sludge can be discharged.

- By standardizing the “drain part exchange type” for wear countermeasures, even if the drain discharge part wears over time due to sludge of hard materials, you can use it for a long time by replacing parts.

- The main unit has been made approximately 40% smaller while maintaining the filtration accuracy and defoaming mechanism of the old type. As a result, the motor capacity of the supply pump can be reduced by 40-50%.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material Non-magnetic material |

| Processing details | Grinding Cutting |

| Work material | FC/FCD Steel Aluminum Stainless Copper Titanium Carbide Mixed chips (aluminum + FC or sintered metal) |

| Chip shape | Sandy |

| Grinding chip size | Ultrafine particles (5 μm to 10 μm) Fine particles (10 μm to 100 μm) Coarse particles (0.1 mm to 0.5 mm) |

| Machine tool | Grinding machine Tool grinding machine Machining center NC lathes Induction hardening machine Cutting specialized machine Washing machine |

Product introduction video

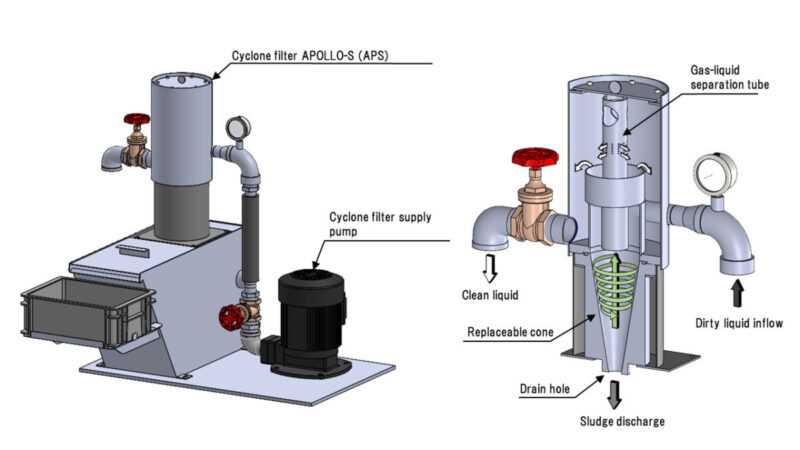

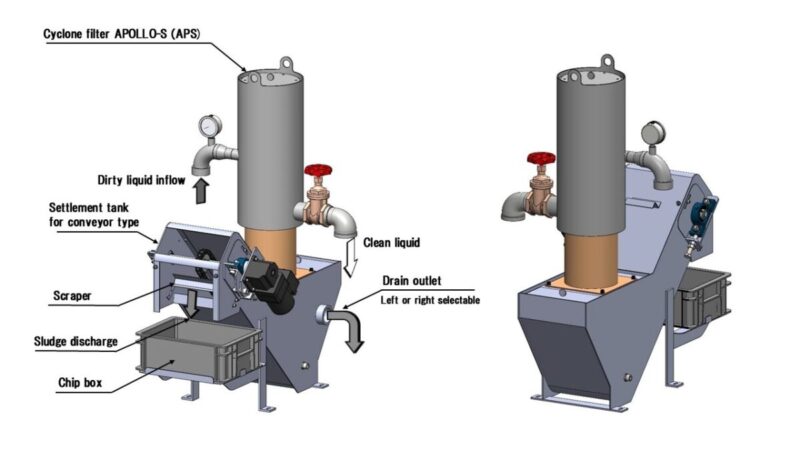

Mechanism

- The dirty liquid flows into the main body due to the action of the APOLLO supply pump.

- The dirty liquid is rotated at high speed inside the main body, and chips and sludge are separated by centrifugal force.

- The separated chips and sludge are discharged from the drain port at the bottom of the main body.

- The foam is taken out of the clean liquid when it passes through the gas-liquid separation pipe and sent to the outside of the main body.

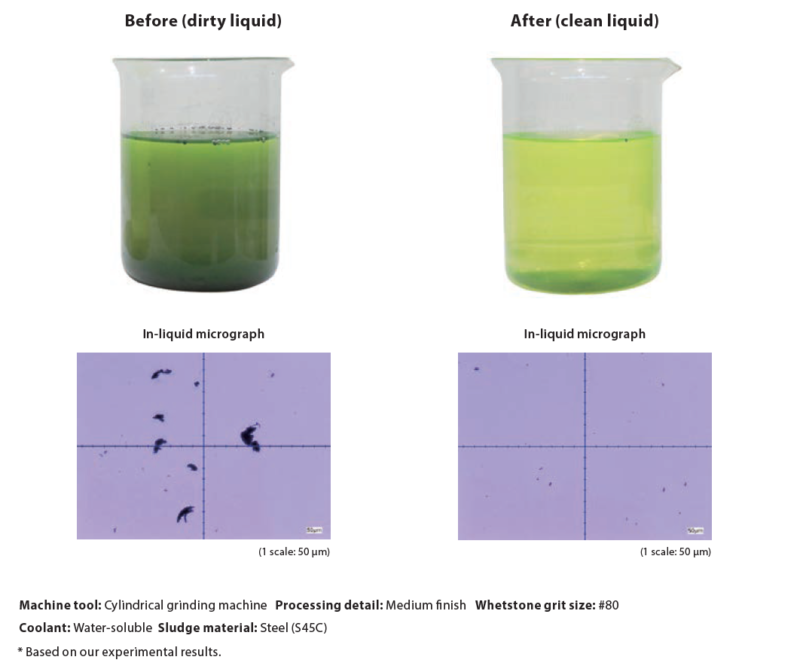

Before-and-after coolant status by filtration

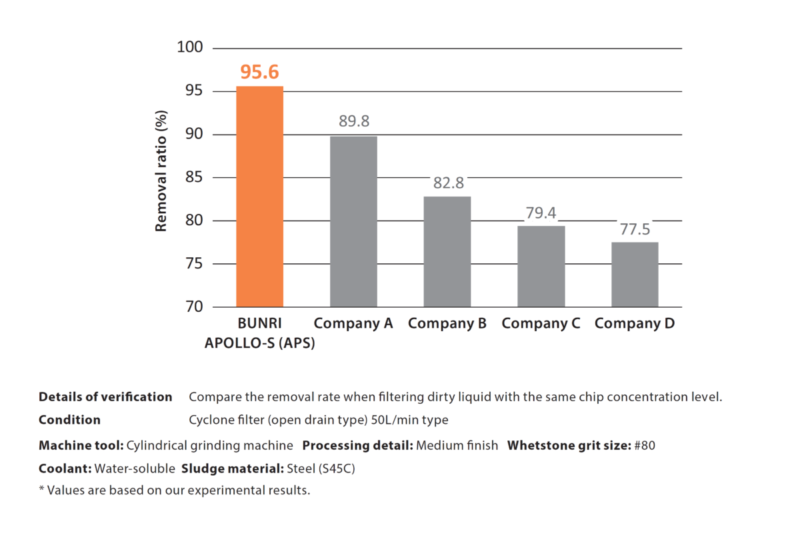

Comparison of removal rate with other companies' cyclones

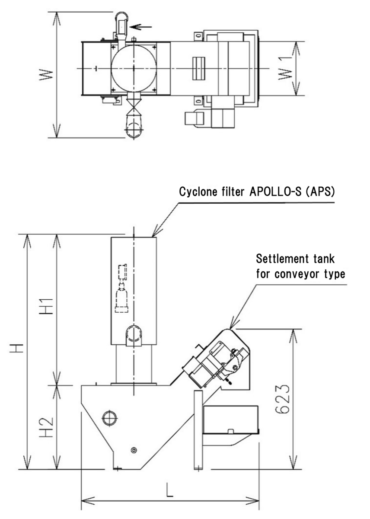

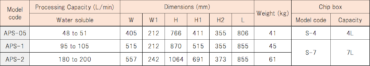

Specifications

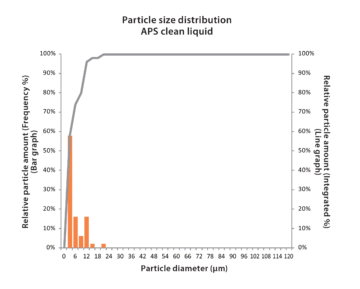

Filtration accuracy

10 μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Grinding machine

Coolant: Water soluble

Processing flow rate: 100 L/min

Chip material: Steel

Processing flow rate

Water soluble

- APS-05 48 to 51 L/min

- APS-1 95 to 105 L/min

- APS-2 180 to 200 L/min

Product weight

- APS-05+SH 41kg

- APS-1+SH 45㎏

- APS-2+SH 61㎏

* The product weight varies depending on the specifications, options, etc.

Paint color

Medium metallic (Approximate color: Munsell No. N-6.7)

* For information about the specified color, please consult us.

Drive motor

25W (Settlement tank for conveyor type)

Supply pump

- APS-05 55 L/min×0.22 MPa or more

- APS-1 110 L/min×0.23 MPa or more

- APS-2 210 L/min×0.26 MPa or more

* For details on how to select the supply pump, please contact us.

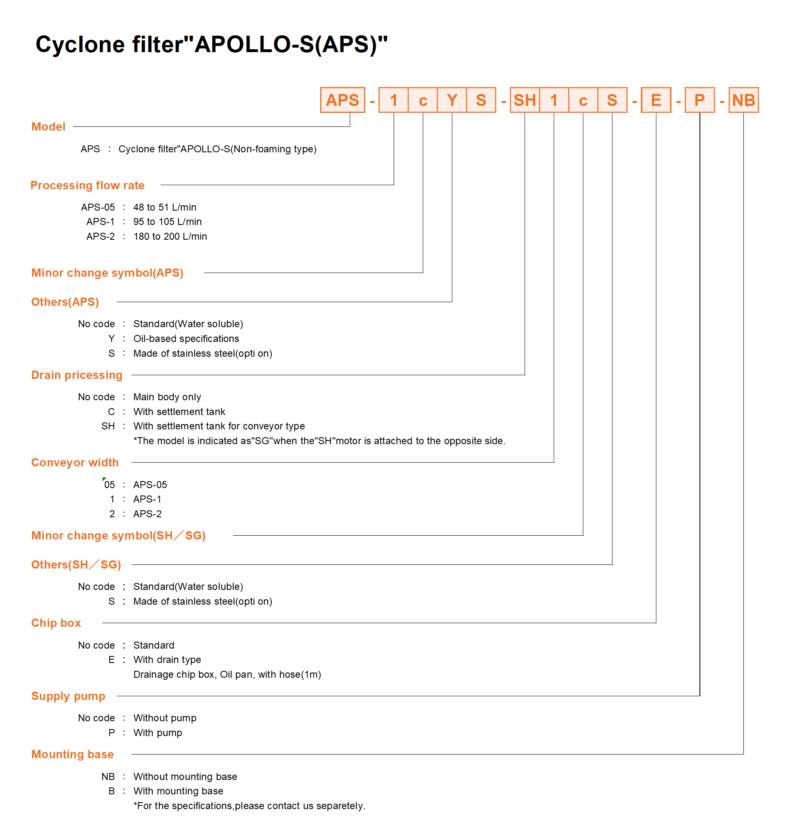

Model code

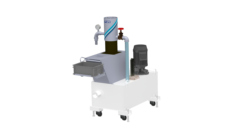

Product Photo (Example)

Chip discharge image

Settlement tank for conveyor type

Settlement tank

* Photos are product images for illustration purposes only. Specifications differ from the actual product.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* When the oil viscosity exceeds 10 mm 2/s, please consult us.

* For details on how to select the supply pump, please contact us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.